Freeprint splintmaster taff (functional splints)

Freeprint splintmaster – tough

DETAX FREEPRINT® SPLINTMASTER taff – flexible high-end splints (TAFF)

Biocompatible premium material for 3D printing clear-transparent splints. SPLINTMASTER taff stands for particularly high impact strength and pronounced recovery – the splint reliably returns to its original shape, remains long-lasting and does not become brittle. The finely tuned material properties enable tension-free wearing comfort and easy insertion and removal . Odorless and tasteless, free of MMA, THF-MA, and TPO . Color: Clear-Transparent.

Note: Available in two levels of flexibility – TAFF (dynamic-firmer) & FLEX (more compliant).

Highlights

-

Break-resistant: Very high impact strength – stable even under high pressure

-

Shape memory: High recovery for precisely fitting, long-lasting splints

-

Tension-free wearing comfort: Gentle insertion/removal, comfortable to wear

-

Permanently color-stable: Retains its clear appearance over a long period of time

-

Safe for everyday use: Odorless and tasteless, MMA/THF-MA/TPO-free

-

Indications

Bite/therapy splints (high-end) according to IFU/processing instructions. -

shade

Clear-Transparent -

Wavelength: 385 nm.

| EU MDR / Status | IIa |

|---|---|

| Health Canada | Class II License |

| FDA | – |

Core properties: Tensile strength >40 MPa; tensile elongation >20%; tear strength >140 N/mm; hardness >75 Shore D; water absorption <32 μg/mm³; solubility <5 μg/mm³

EN

Wavelength: 385 nm.

| EU MDR / Status | IIa |

|---|---|

| Health Canada | Class II License |

| FDA | – |

Key properties: Tensile strength >40 MPa; tensile elongation >20%; tear strength >140 N/mm; hardness >75 Shore D; water absorption <32 μg/mm³; solubility <5 μg/mm³

All technical information is without guarantee, please refer to the manufacturer's IFU/SDS.

Pairs well with

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQs

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

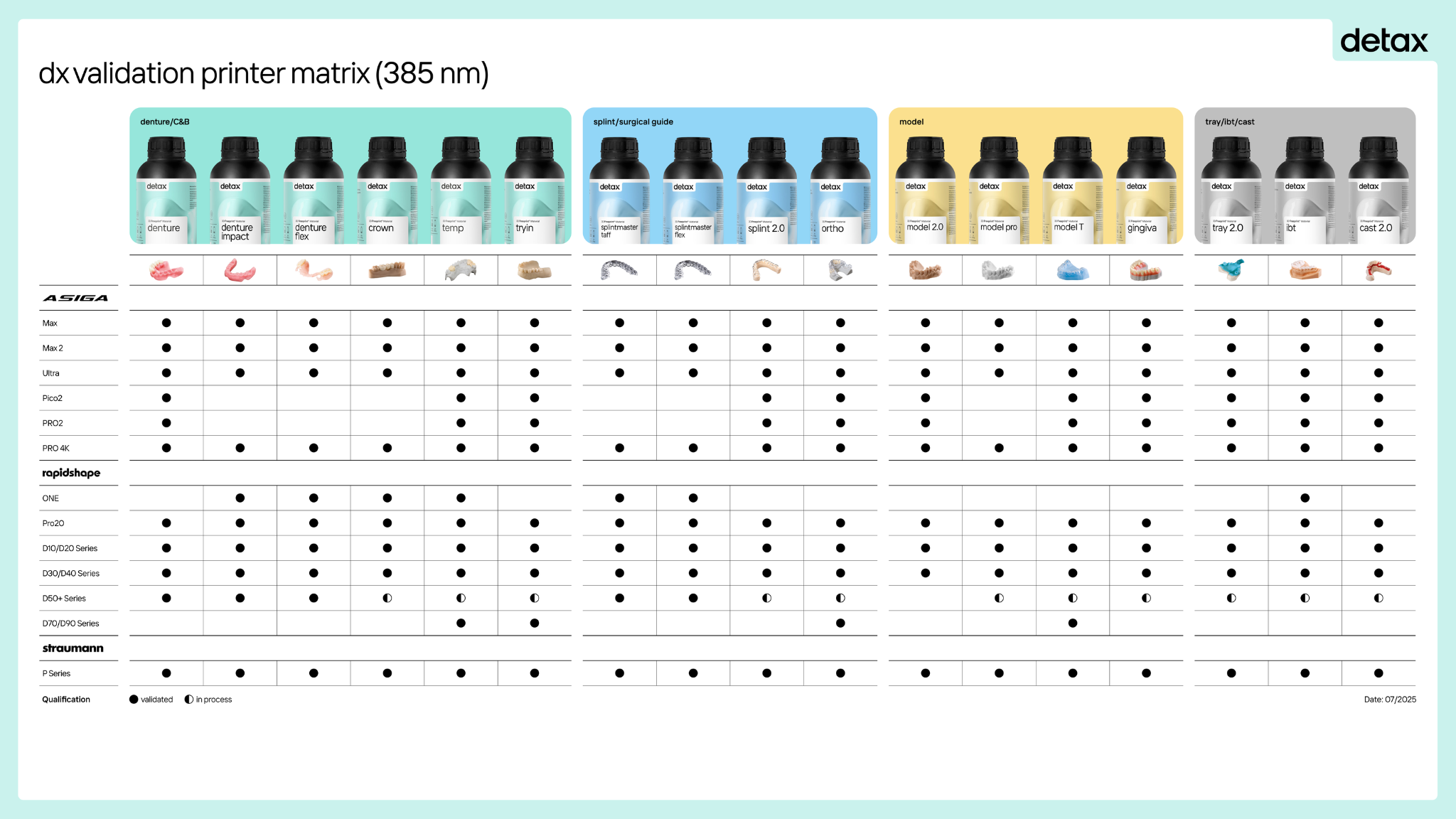

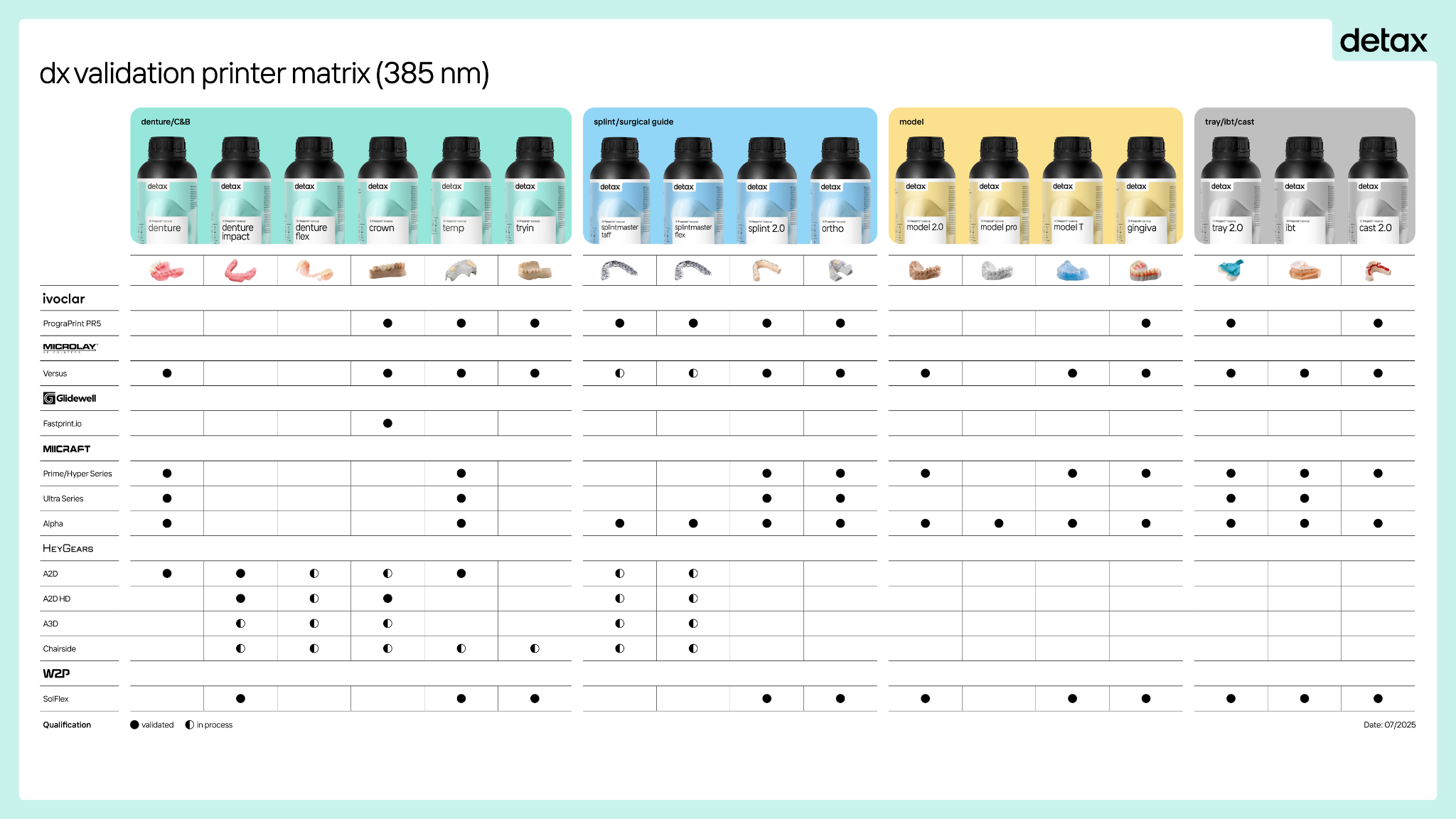

Compatibility & Workflow

- Printers: For common dental DLP/LCD printers in the 385–405 nm spectrum (please note material-specific approvals).

-

Post-processing: Coordinated cleaning and post-curing processes for durable end results.

-

Application: From CAD design to printing to polishing/post-processing – optimized for short turnaround times.

FAQ about DETAX Freeprint 3D printing resins

What applications are Freeprint resins intended for?

Splints/rails, surgical drilling templates (Guide), individual impression trays/base plates (Tray 2.0), model production (Model) and depending on the range: Gingiva/Mask, Cast/Wax (burn-out), Ortho/IBT.

Which 3D printers are the resins compatible with

Compatible with common dental DLP/LCD systems in the 385–405 nm spectrum. Please refer to the respective manufacturer's approval/compatibility list.

Do I need special printing parameters?

Yes. Layer thickness, exposure times, and support structures vary depending on the device and material. Use the material-specific parameters from the printer manufacturer's IFU/profiles or DETAX.

Can you mix different Freeprint resins?

No. Do not mix different batches/materials. Always filter any remaining resin and return it to the original bottle , if permitted by the manufacturer.

How do I store the resins correctly?

Store in a cool, dry place, protected from light, and tightly closed. Avoid direct sunlight and high temperatures. Shake well before use (according to the International Union for Food and Agriculture).

How long does the material last?

See the best-before date on the bottle. Use promptly after opening and handle cleanly to avoid contamination.

What advantages do DETAX Freeprint resins offer in everyday life?

High precision fit , reliable processes, clean surfaces , fast construction times and reliable reproducibility – ideal for practice and laboratory.